In the industrial piping system, check valve is the key equipment to prevent the backflow of media. Butterfly check valves and swing check valves, although similar in function, differ significantly in structural design, application scenarios, etc. Kist Valve Group will analyze the differences between these two types of valves in layman's terms for you.

I. Basic function description

Butterfly check valves and swing check valves are both devices used to prevent backflow of liquids, and both can realize the protection functions such as light-load starting pumps and eliminating water hammer. The core component of both is a rotatable disk-shaped valve plate, but the specific structure and application scenarios are significantly different.

Second, the butterfly check valve and swing check valve 5 core difference comparison

1, industry standard differences

Butterfly check valve mainly follows:

CJ/T 282-2008 (urban water supply standards)

JB/T5299-2022 (industrial control standards)

Swing check valve applicable standards:

GB/T 12236 (petrochemical industry)

API6D (International Petroleum Standard)

GB/T 13932 (general industrial standards)

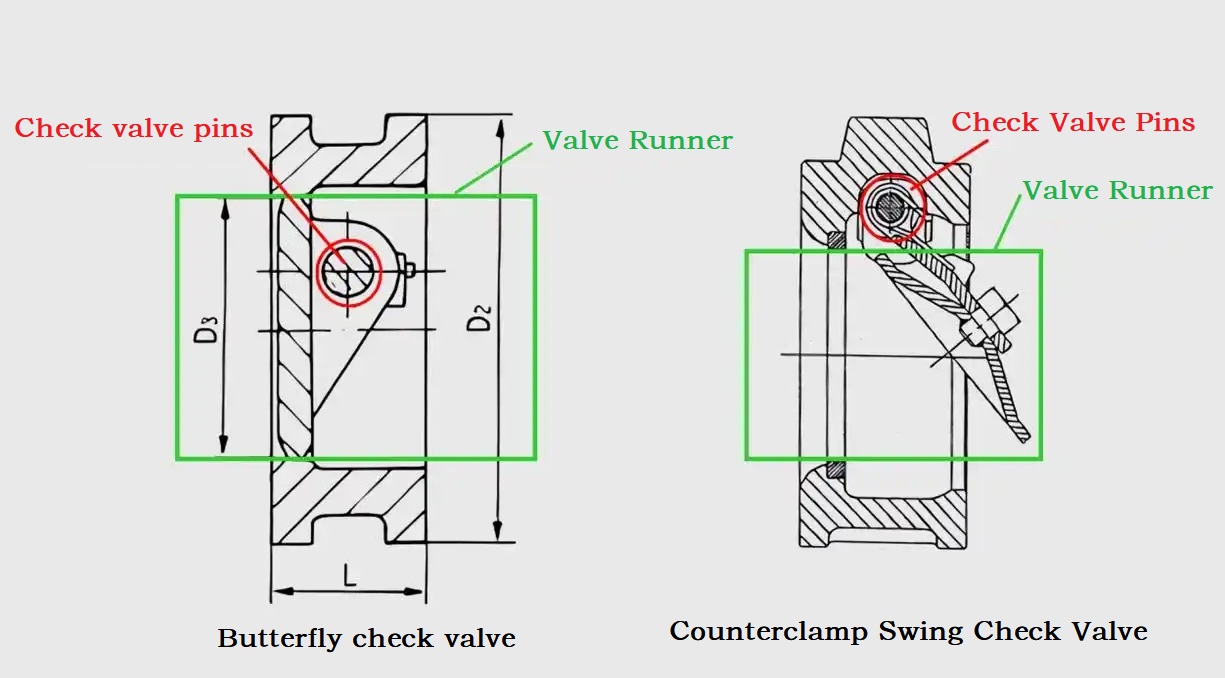

2、Mechanical structure comparison

The key difference lies in the position of the rotary axis:

Butterfly type: the rotating shaft passes through the center of the valve plate and is located inside the flow path.

Swing-open type: the spindle is at the edge of the sealing surface, located in the outside of the flow path.

Schematic illustration:

Butterfly → | valve plate | shaft in center

Swing-away → edge of valve plate → shaft outside

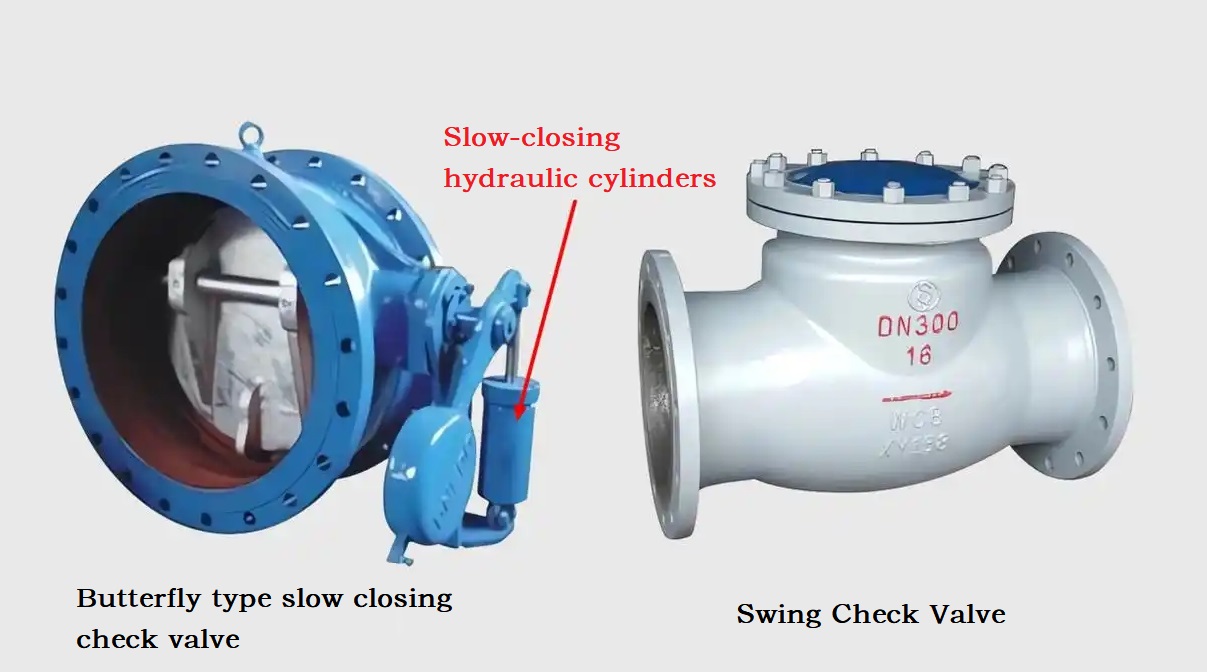

3、Slow-close design application

Butterfly check valves (especially large diameter type):

Standard with slow-closing structure (e.g. pipe force valve, hydraulic valve)

Effective relief of water hammer

Applicable pipe diameter: maximum DN5000

Ordinary models without slow closing function

Special models such as HH44X with slow closing

Commonly used pipe diameter: DN15-DN600

4、Differences in applicable scenes

Butterfly type is more suitable for:

Water system

Low/medium pressure pipelines

Clean water environment

Rotary type is more applicable to:

Water/steam/oil/chemicals

Low/medium/high pressure environments

Wide choice of materials (cast iron to special alloys)

5、Piping connection

Butterfly type is commonly used:

Flange connection (large diameter)

Clamp connection (small diameter)

Swing-open type is optional:

Threaded/flange/welded etc.

Clamp/pair clamp and other special connections

III. Strengths and weaknesses analysis table

| Type | Strengths | Weaknesses |

| Butterfly | Small size, light weight, fast switching, suitable for large caliber | Weak sealing, not suitable for impurity media |

| rotary open | Good sealing, high pressure and temperature resistance, easy maintenance | Complex structure and high cost |

IV. Decision-making guide for selection

Selection of butterfly type case:

✓ Limited installation space

✓ Need to close quickly

✓ Conveying clean medium

The case of selecting the rotary opening type:

✓ Medium contains impurity particles

✓ High pressure/high temperature conditions

✓ Multiple connections required

Practical application recommendations:

Check media properties (cleanliness/viscosity).

Confirm system operating pressure rating

Measure actual installation space in piping

Evaluate maintenance accessibility needs

Consult with a qualified technician for confirmation

V. Maintenance Points

Butterfly maintenance points:

Regularly check the spindle lubrication

Pay attention to seal wear

Clean up the deposits in the valve cavity

Rotary type maintenance points:

Check hinge mechanism flexibility

Monitor sealing surface integrity

Prevent impurities from jamming the valve plate

By understanding these key differentiators, users can select the most appropriate type of check valve for their actual project needs, ensuring the safe and efficient operation of their piping system. It is recommended to keep this guide as a reference manual for selection, so that when encountering a specific project, you can make a quick comparison decision.