Safety Valve Technical Analysis Report

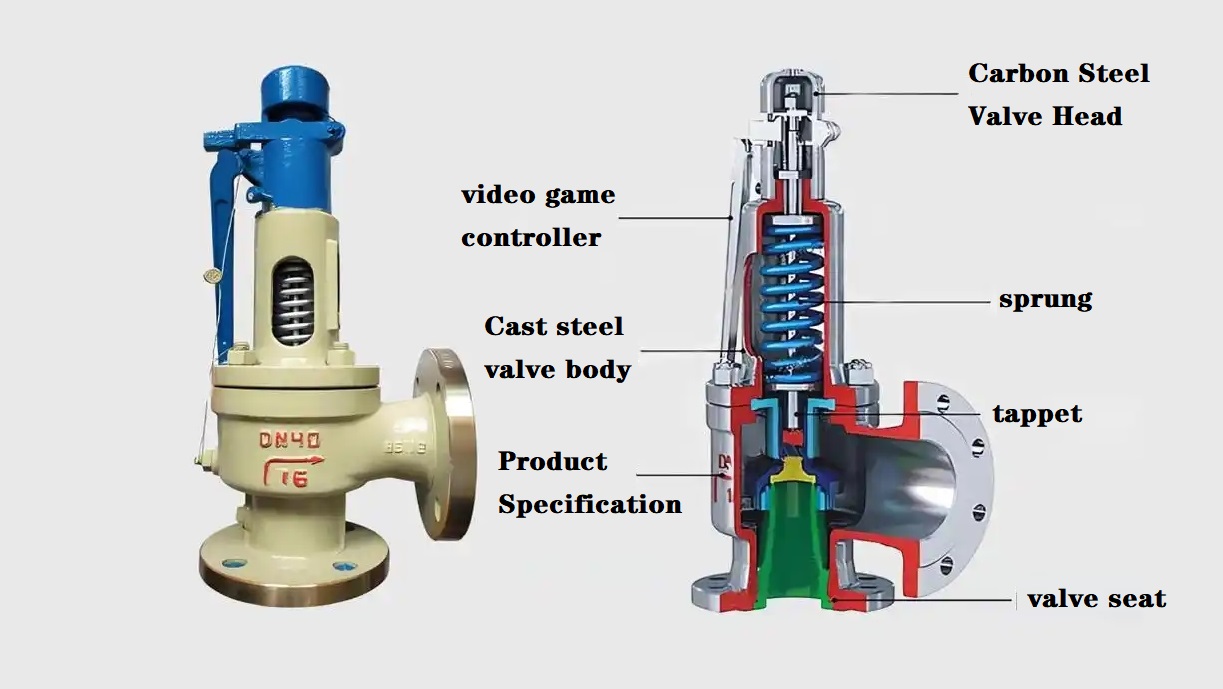

As critical pressure protection devices, safety valves are widely used in boiler systems, pressure pipelines, and container systems. Their operating principle is as follows: When internal system pressure exceeds a preset threshold, the valve automatically opens under the medium's own pressure to discharge excess fluid, thereby reducing system pressure. Once pressure returns to normal operating range, the valve automatically closes, ensuring equipment safety. Structural Characteristics and Differences Between Low-Lift and Full-Lift Safety Valves Please read on.

I. Safety Valve Technical Standard System

Key current technical standards include:

1. Fundamental Standards

GB/T 12241-2021 General Requirements for Safety Valves

GB/T 12242-2021 Performance Test Methods for Pressure Relief Devices

2. Product Standards

GB/T 12243-2005 Spring-Loaded Direct-Acting Safety Valves

GB/T 28778-2023 Pilot-Operated Safety Valves

API 526 Flanged Steel Pressure Relief Valves

3. Dimensional Standards

JB/T 2203-2013 Structural Lengths of Spring-Loaded Direct-Acting Safety Valves

II. Classification and Technical Characteristics

Based on disc opening height and structural features, safety valves are categorized into low-lift and full-lift types. A technical comparison is provided below:

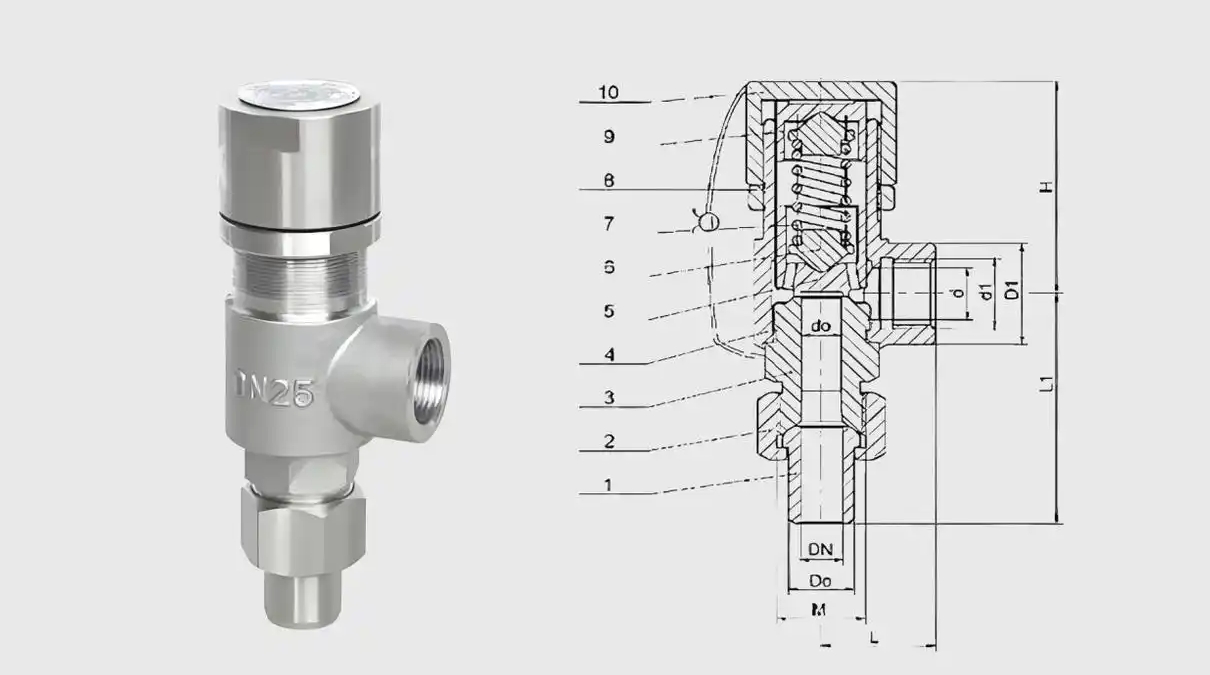

(1) Low-Lift Safety Valves

Structural Principles

Opening height: 1/40 to 1/20 of the seat throat diameter, proportional to medium pressure.

Operation: Gradual opening and incremental reseating after pressure reduction.

Discharge area: Determined by the cylindrical/conical channel formed between the seat and disc.

Technical Parameters

Opening Ratio Discharge Coefficient

1/40 throat 0.14–0.16

1/20 throat 0.07–0.08

Application Features

Application Features

Media: Liquids, low-pressure gases, and steam.

Structural design: Seat diameter is one size smaller than nominal diameter (e.g., DN50 valve paired with a 40mm seat).

Model series: A21H/Y, A41H/Y, A47H/Y.

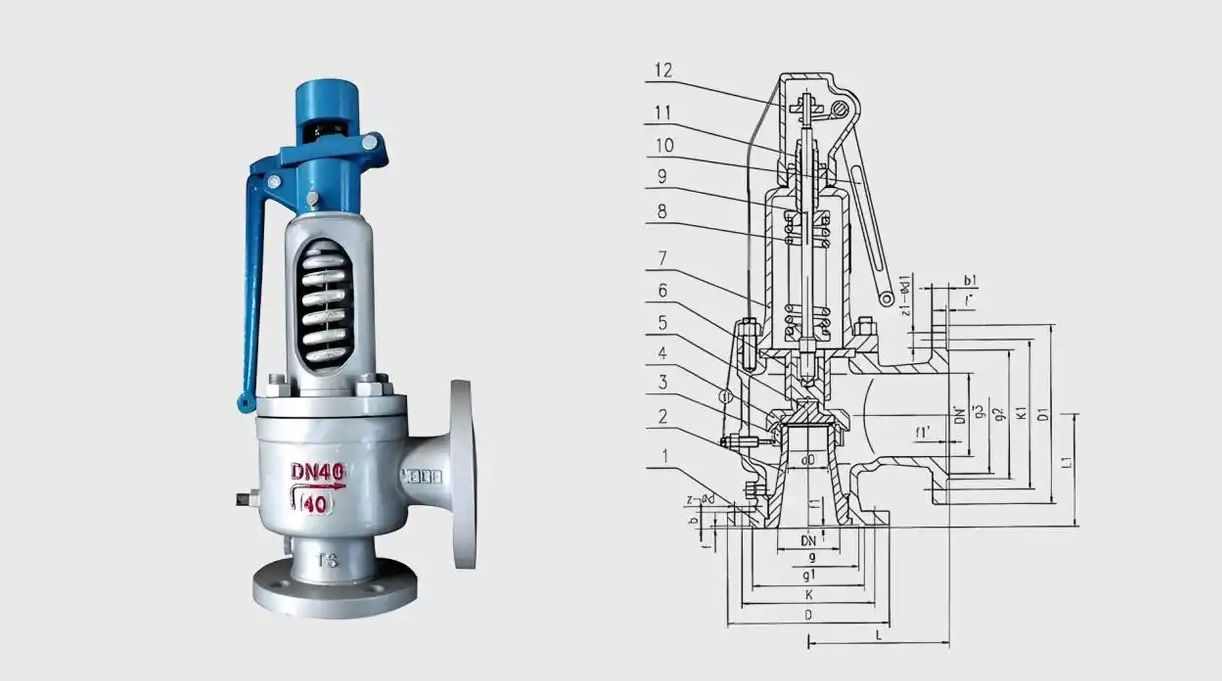

(2) Full-Lift Safety Valves

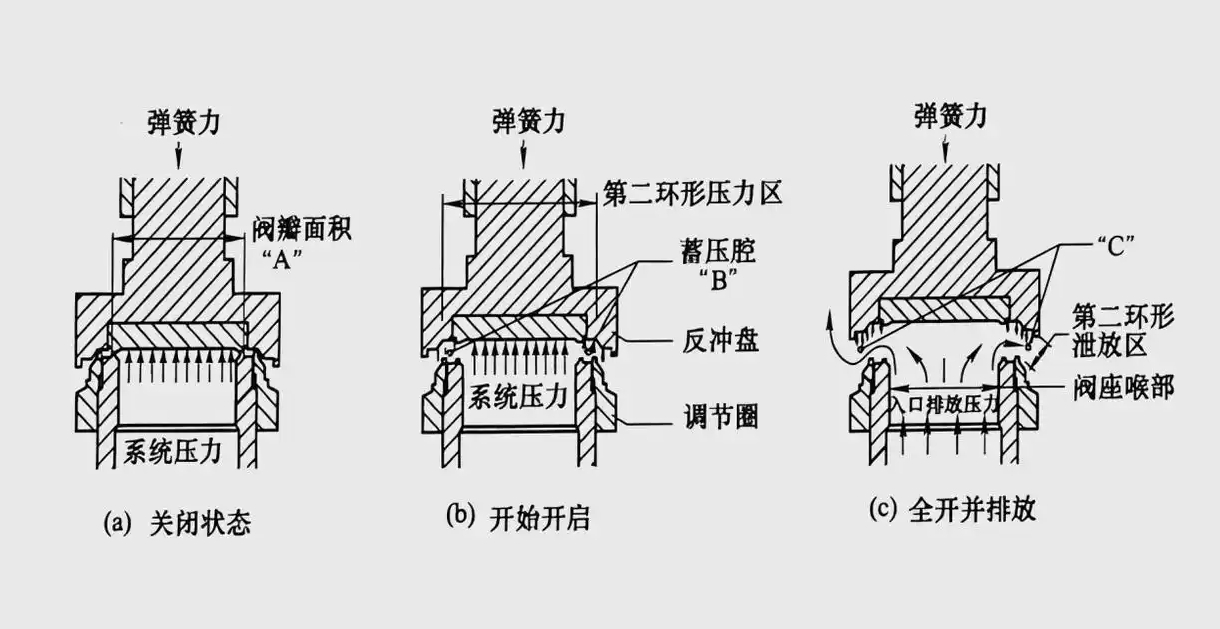

Structural Principles

Opening height: Reaches 1/4 of the seat throat diameter, with discharge area equal to the full flow channel cross-section.

Operation: Two-stage opening via reverse flow disk mechanism (initial low-lift → full-lift under medium counterforce).

Reseating: Snap-action full opening followed by instantaneous reseating.

Technical Advantages

Discharge coefficient: 0.7–0.8 (5–10 times higher than low-lift valves).

Structural design: Seat diameter is two sizes smaller than nominal diameter (e.g., DN50 valve paired with a 32mm seat); outlet diameter increases by one size (e.g., DN65).

Model Series

A42H/Y, WA42H/Y (bellows type), A44H/Y, A48H/Y.

III. Selection Guidelines

1.Medium properties:

Use low-lift valves for incompressible fluids (liquids).

Use full-lift valves for compressible media (steam/gases).

2.Pressure relief requirements:

Full-lift valves are mandatory for rapid pressure reduction scenarios.

3.Installation conditions:

Account for inlet/outlet diameter differences; full-lift valves require outlet expansion design.

This analysis strictly complies with relevant national standards and systematically outlines the technical principles, classification criteria, and selection guidelines for safety valves, providing robust technical specifications for equipment selection and application.