What is a knife gate valve?

Knife gate valve is a special type of flat gate valve, adopting the design of clamped connection, with shorter body length and thinner gate structure. Its core feature is that the bottom of the gate with a knife-shaped slash, can effectively cut off the medium of fibers or particles, so the name “knife gate valve”. The valve is widely used in slurry, coal dust, pulp, slurry and other solid-liquid/gas mixtures containing transportation scenarios, the working pressure usually does not exceed the PN16 standard.

Knife gate valve industry implementation standards

The current mainstream implementation standards include:

1, JB/T8691-2013 “no bonnet knife gate valve

2、JB/T53200-1999

3、MSS-SP81-2001《Knife Gate Valve

Unflanged vs Flanged

The standards mentioned above are primarily for uncovered knife gate valves. When this type of valve is open, the gate is exposed to the outside of the valve. If the valve is left open for a long period of time, dust and impurities in the environment can easily stick to the surface of the gate. This makes it difficult to close the valve and tends to cause wear of the sealing packing (which prevents leakage of media) at the gate, eventually leading to leakage problems.

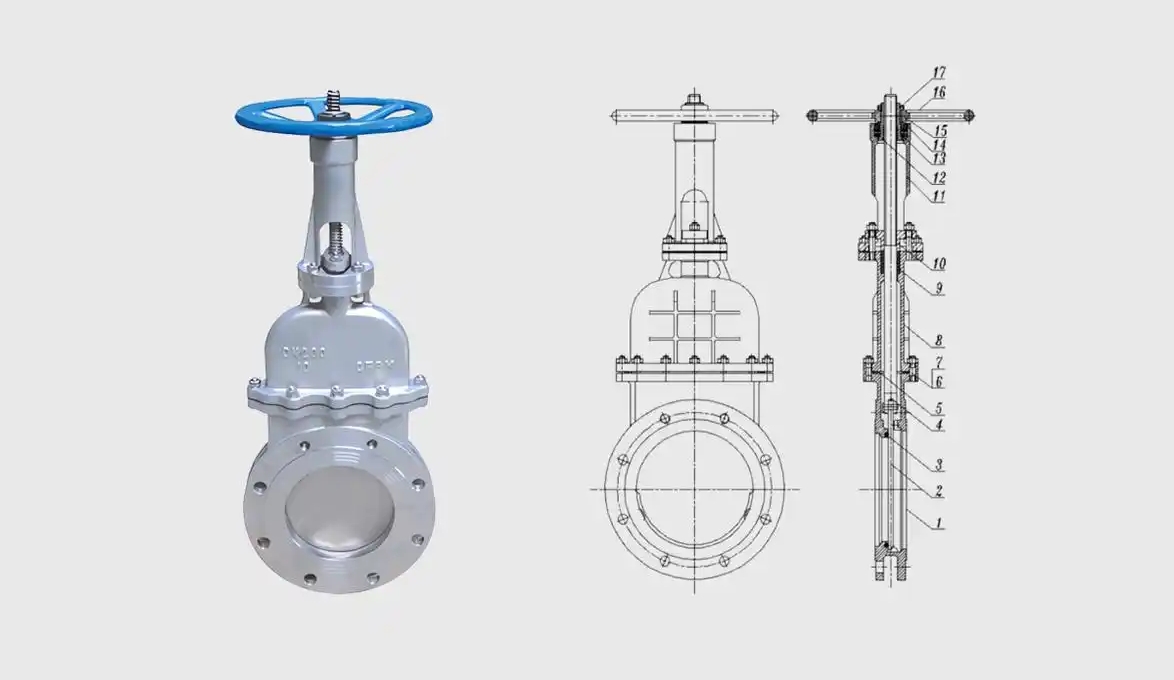

In order to solve this problem, the bonneted knife gate valve has been designed. It is similar in structure to our common ordinary gate valves, with a valve body and bonnet, which together form a closed protective shell that completely encases the gate plate inside. Only the valve stem will protrude through the bonnet and is sealed with packing at the penetration.

The benefits of this construction are:

Better sealing: The frictional resistance of the stem packing is much less than that of the gate seal in a bonnetless valve, resulting in a more reliable seal.

Less effort to open and close: Because there is less friction, less force (torque) is required to open and close the valve.

Longer service life: The gate is closed and protected from outside contamination and damage, extending the service life of the valve.

Open stem vs concealed stem

Knife gate valves can also be operated in two ways:

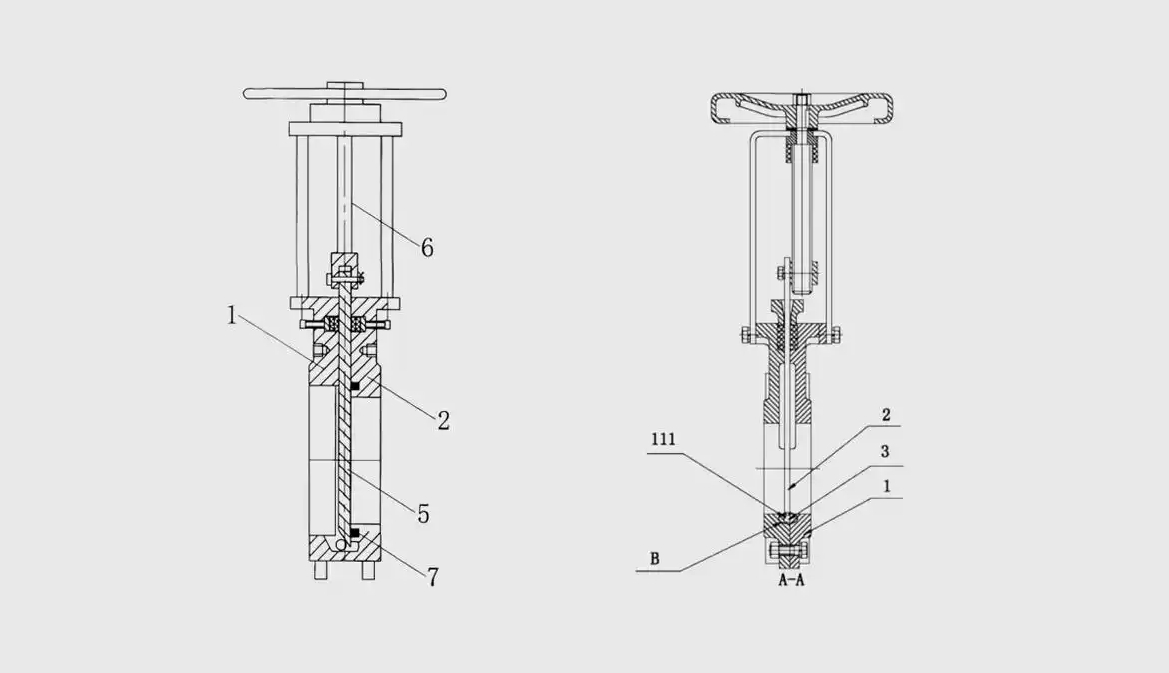

Open stem: The valve stem is up and down movement. When the valve opens or closes, the valve stem and gate are lifted together. You can directly see from the position of the valve stem lift whether the valve is open or closed.

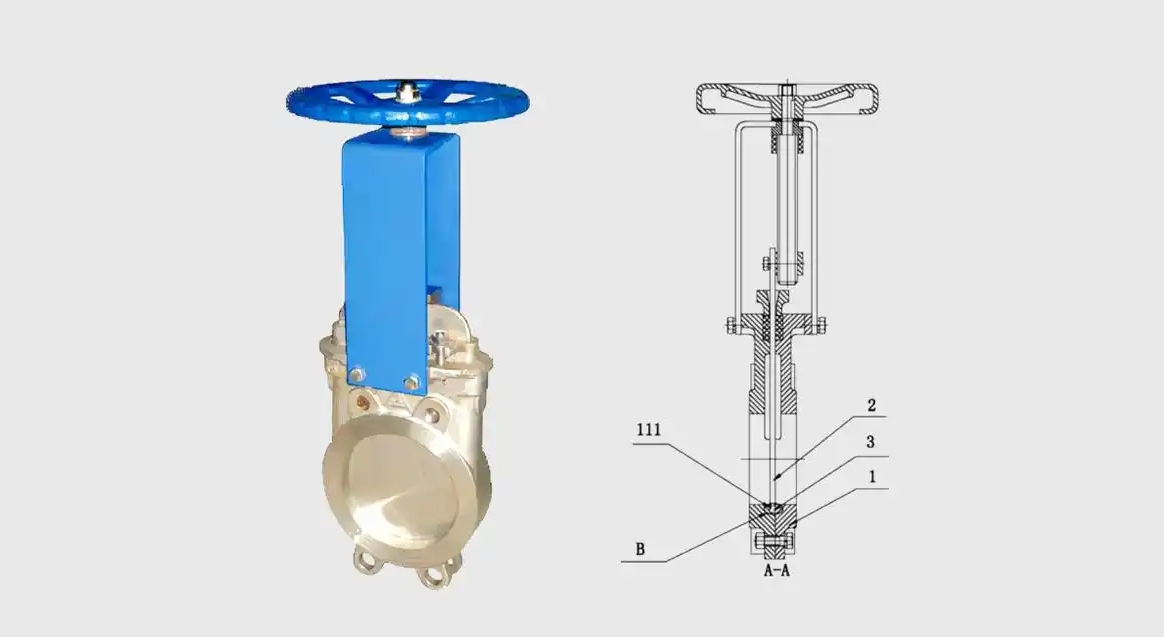

Concealed stem: The stem rotates in place. The nut is fixed on the gate plate, and when the stem rotates, the nut drives the gate plate up and down. The stem itself remains the same height. This design is particularly useful where the installation space is of limited height (not tall enough).

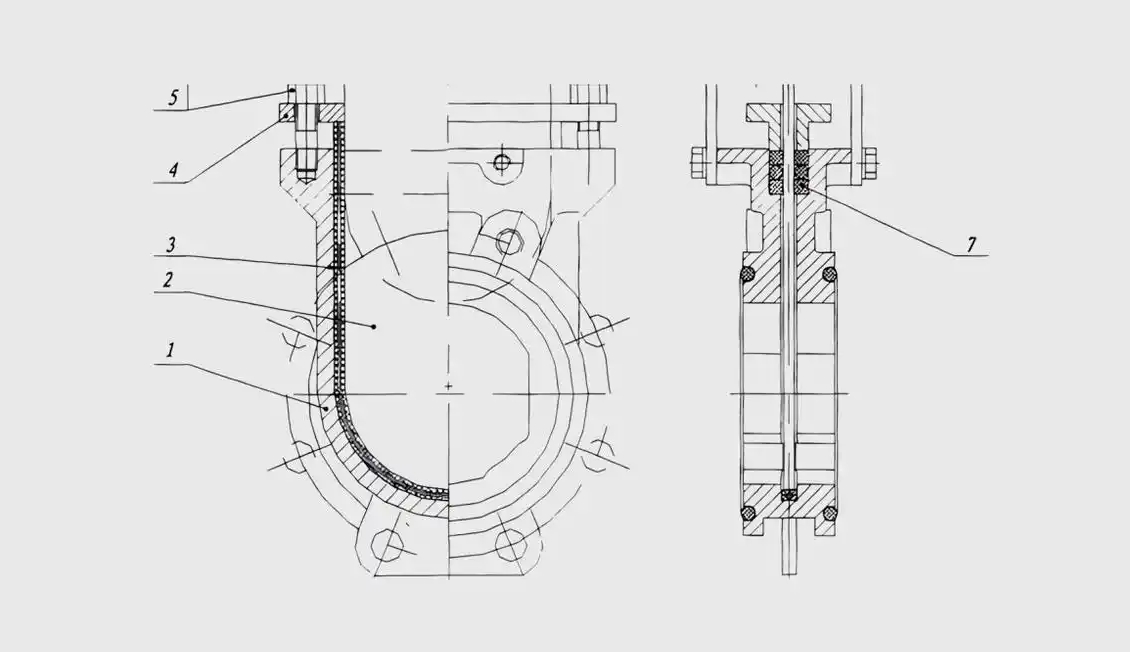

Valve Body Structure: Split Type vs Integral Type

There are two ways to manufacture the valve body of a knife gate valve:

Split type: The valve body is manufactured in two parts and then bolted together. This structure is more convenient processing and maintenance.

Integral: the valve body is a whole casting molding. This structure is stronger, and the risk of leakage of the valve body itself is also smaller.

Sealing form analysis

1、Elastic sealing strip structure (common in Z73X-10 type)

Valve body cavity with grooves embedded in the hollow core rubber strip

When closing, the gate plate squeezes the sealing strip to form a seal.

When opening, the sealing strip automatically rebound reset

Features: anti-sedimentation design, suitable for slurry media

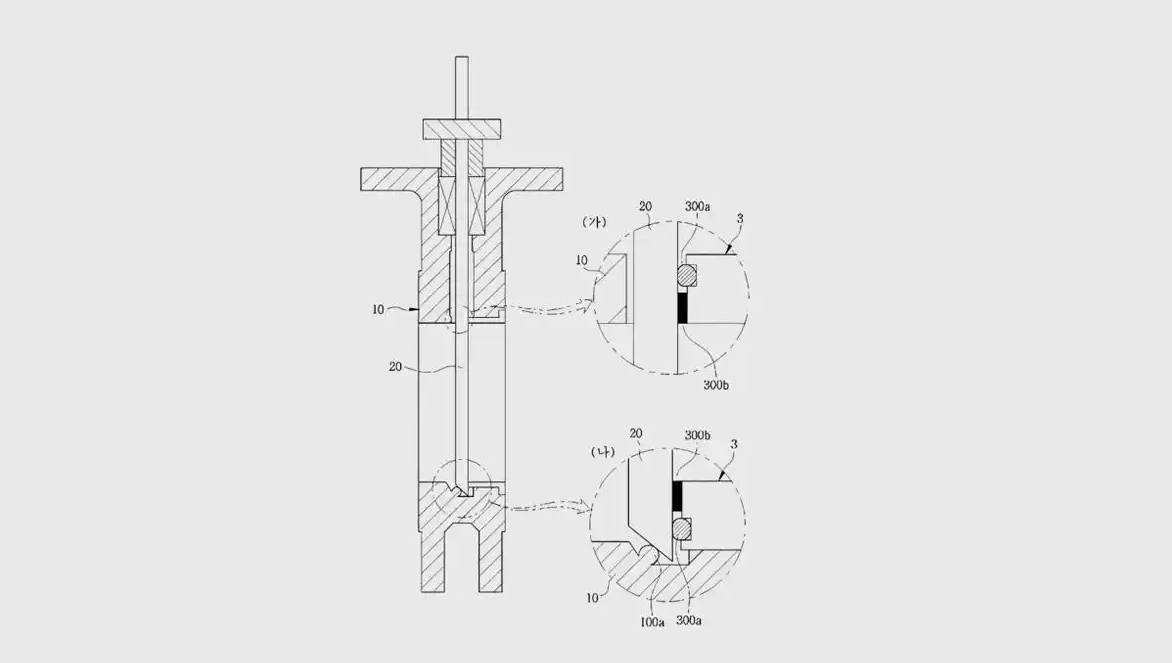

2、Double composite seal (common in PZ73X-10 type)

Rubber O-ring + metal hard seal combination

O-ring independent seal at low pressure, high pressure to form a metal - rubber double seal

Advantage: seal ring can be replaced, adapt to a wide range of pressure

Common sealing structure:

Structure I (commonly used in slurry valves such as Z73X-10):

A groove is machined in the internal cavity (center cavity) of the valve.

An elastic sealing strip (preferably hollow rubber sealing strip) is placed on this groove.

When closing the valve, the gate moves downward. The sharp bottom edge of the gate plate presses against the sealing strip and presses it into the groove, thus realizing the seal between the gate plate and the valve body.

When the valve is opened, the gate moves upward, leaving the sealing strip, which springs up by its own elasticity and returns to a state flush with the groove.

Advantages: This structure can effectively prevent solid particles from accumulating in the groove, ensuring good sealing performance. It is especially suitable for conveying slurry and other easy-to-sediment media.

Structure II (common models such as PZ73X-10):

Rubber O-ring (soft seal) and metal sealing surface (hard seal) are installed on the valve seat at the same time.

The o-ring protrudes slightly more than the metal sealing surface.

Low pressure: the medium pressure is low, only the elastic deformation of the O-ring is needed, and the seal can be realized against the gate plate, which is very effective.

High Pressure: The gate plate contacts and compresses the o-ring first, then continues downward, and eventually the gate plate and metal sealing surface are also tightly adhered to form a double seal of o-ring + metal surface.

Advantages:

O-rings deform only within their elastic range, are not easily damaged, and have a long life.

O-rings are relied upon to provide excellent sealing at low pressures.

Double protection at high pressures.

O-rings are easy to replace when worn.

The beveled angle at the bottom of the gate fits into a stop on the valve body, ensuring that the gate fits tightly against the seat when closed.

Method of actuation (how the valve is opened and closed)

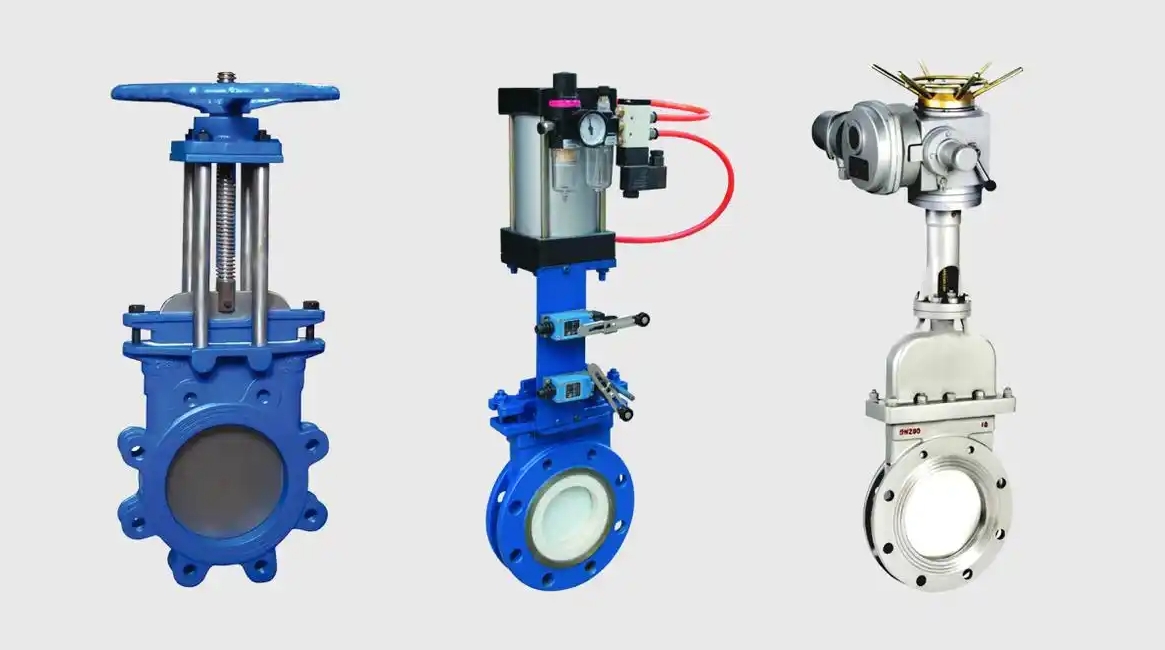

Knife gate valves can be operated (actuated) in a variety of ways:

Manual: Directly opened and closed with a handwheel or handle.

Pneumatic: Use compressed air to push the cylinder to open and close the valve. Accessories such as solenoid valves (to control the direction of air flow), filtering and pressure reducing valves (to purify and stabilize air pressure), and travel switches (to provide feedback on the position of the valve) are required. Also need to consider whether the need for explosion-proof (for flammable and explosive environment). Representative models: PZ673X (soft seal), PZ673H (hard seal).

Electric: The valve is opened and closed by an electric motor (electric actuator). When selecting the type, it is necessary to consider the voltage of the actuator (e.g. 220V, 380V), the control mode (switching type, regulating type), and whether or not it needs to be explosion-proof. Representative models: PZ973X (soft seal), PZ973H (hard seal).

Hydraulic: The pressure of hydraulic oil is used to push the cylinder to open and close the valve. Can be a motor + hydraulic pump integrated “electro-hydraulic” actuator, can also be a separate hydraulic cylinder (need to support the hydraulic station to provide power oil). Representative model: Z773X.

Sprocket drive: When the valve is installed in a high position and manual operation is inconvenient, it can be operated from the ground by chain and sprocket mechanism.

Kist Valve Group Knife gate valves are particularly good at handling media containing solid particles, fibers, or easy to precipitate, thanks to their short bodies, thin gate plates, and sharp “knife mouths”. Considerations for selection:

Operating conditions: media type (wet/dry, particle size), pressure, temperature.

Configuration: uncovered or covered? Open or concealed rod? Split or integral?

Sealing: Soft seal (zero leakage, but not resistant to high temperature wear)? Hard seal (resistant to high temperature and wear, but allows a small amount of leakage)? Or composite seal (both)?

Drive: manual, pneumatic, electric, hydraulic or sprocket? Choose according to ease of operation, automation requirements and working conditions (e.g., whether explosion-proof is required).