First, what is a hydraulic control valve?

Hydraulic Control Valve (Hydraulic Control Valve) is not the name of a single valve, but a series of valves that control the piping system through the energy of water pressure. These valves through the combination of the main valve and pilot valve, the use of water pressure, kinetic and potential energy to achieve different functions. Mainly based on CJ/T219 and JB/T10674 industry standards for classification.

Kist Valve Group summary: it is the use of water pressure, kinetic energy and potential energy, by a main valve and different pilot valves, components combined into a series of valves with different functions of the general term.

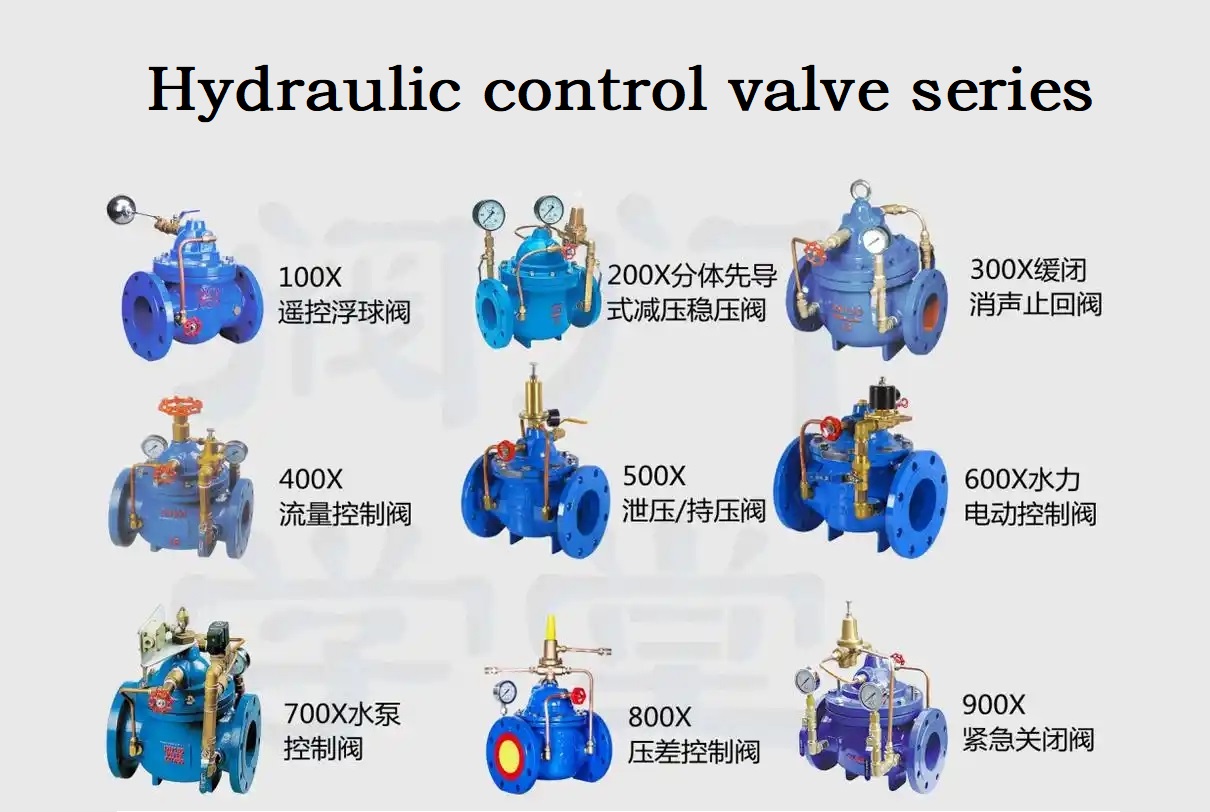

Second, 9 common hydraulic control valve types and uses

According to the latest CJ/T219-2017 standard, hydraulic control valves are divided into the following 9 categories (Note: 300X, 700X, 900X models have been eliminated by the new version of the standard):

1、Remote control float valve (100X)

Function: automatically control the main valve switch through the float with the water level rise and fall, to maintain the pool / tank level stable.

Scenario: commonly used in high-rise building water tanks, fire fighting pools.

2、Adjustable pressure reducing valve (200X)

Function: No matter how the inlet pressure or outlet flow changes, it can stabilize the outlet pressure at the set value and the pressure is adjustable.

Characteristics: In line with the special standard CJT 256-2007 (2016 updated version), regular debugging is required to ensure accuracy.

3、Slow-closing muffler check valve (300X, eliminated)

Original function: reduce water hammer noise and prevent pipeline vibration by delaying the closure of the main valve.

Reason for elimination: replaced by multifunctional pump control valve (CJ/T 167-2016), which integrates slow closing and water hammer elimination function.

4、Flow control valve (400X)

Function: Automatically maintain a constant outlet flow, even if the inlet pressure fluctuations, the flow can still be adjusted.

Application: industrial piping systems that require precise flow control.

5、Pressure relief/pressure holding valve (500X)

Function: automatically relieve pressure when the pipeline pressure exceeds the set value, and close it after the pressure is restored.

Commissioning points: need to adjust the pressure relief threshold according to the pipe network pressure capacity.

6、Hydraulic electric control valve (600X)

Function: Remotely control the main valve switch by electric signal (such as buttons, sensors).

Advantage: to realize automated pipeline opening and closing, without manual operation.

7, pump control valve (700X, eliminated)

Original function: with the pump start and stop to achieve slow shutdown check, to protect the pump from water hammer.

Alternative: the same multi-function pump control valve (CJ/T 167-2016).

8, differential pressure bypass balancing valve (800X, now called differential pressure control valve)

Function: automatically adjust the differential pressure of the supply and return pipelines to maintain system pressure balance.

Installation points: need to be connected in parallel between the water supply pipe and return pipe, avoid direct series connection.

9、Emergency shut-off valve (900X, eliminated)

Original function: automatically cut off the domestic water pipeline when fire-fighting water, to ensure the priority of fire-fighting water supply.

Reason for elimination: the function has been integrated into other valve models.

Third, the valve structure classification guide

1、Selection according to the main valve structure:

T-type straight-through: low cost, suitable for conventional scenes

Y-type flow-through: smooth flow of water but higher costs

2, according to the control element selection:

Diaphragm type: high sensitivity, suitable for low-pressure pipeline (PN16/25)

Piston type: high pressure resistance (PN40), more convenient maintenance

3, according to the control cavity selection:

Single-cavity: simple structure to prevent leakage

Double cavity type: more accurate control but there is a risk of leakage

Fourth, selection and maintenance points

1、Pressure matching principle:

Low-pressure systems prioritize diaphragm type

High pressure / large diameter must choose piston

2, the principle of functional correspondence:

Need precise control choose double-chambered

Simple system choose single-chamber type

3、Maintenance precautions:

Regular inspection of seals

Poor water quality to strengthen the piston valve maintenance

Attention to the model changes brought about by the standard update

V. Description of the latest standard changes

2017 version of CJ/T219 main updates:

Remove 300X/700X/900X models

New CJ/T 167-2016 standardized products

Standardize differential pressure control valve naming

Hydraulic control valve through the modular design to achieve “a valve multi-functional”, the correct selection can significantly improve the safety and energy efficiency of the pipeline network. It is recommended to consult the manufacturer for specific working conditions and prioritize the products that comply with the latest national standard.