Principle of Pressure Reducing Valve

A pressure reducing valve is a device that reduces the pressure of a high-pressure inlet fluid (gas or liquid) to a stable outlet pressure by adjusting the opening of the internal spool. It automatically maintains a stable outlet pressure even if the inlet pressure or flow rate fluctuates.

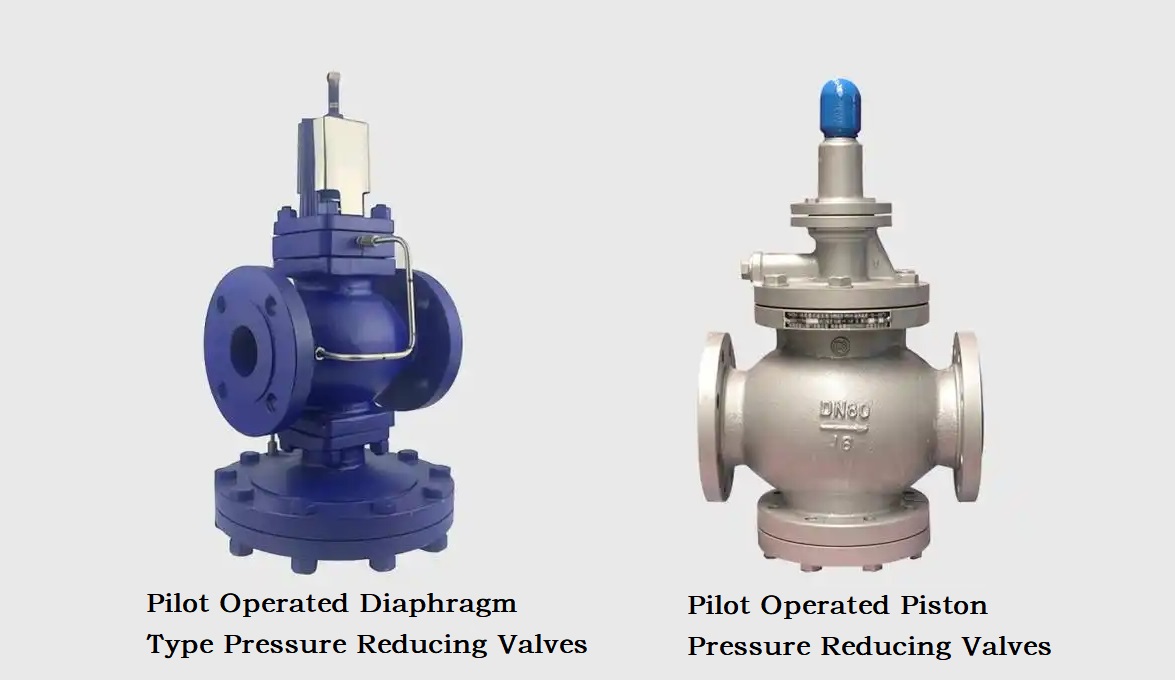

Two main types of pressure reducing valves

Depending on the method of control, pressure reducing valves are categorized as pilot-operated and direct-acting (also known as direct-acting). They differ in structure and performance and are suitable for different scenarios.

First, the structure and principle of pilot-operated pressure reducing valve

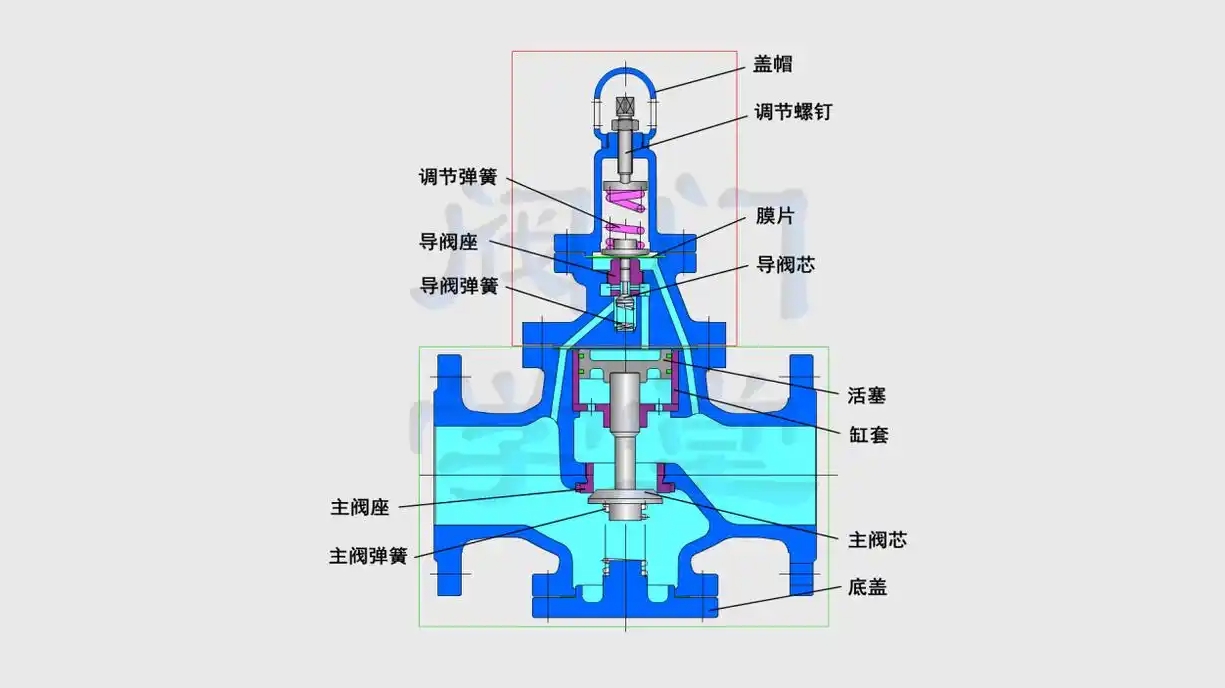

Pilot-operated pressure reducing valve consists of two parts: the pilot valve and the main valve, and the working principle is similar to the “master-servant collaboration”:

Pilot valve: monitor the outlet pressure changes. When the pressure fluctuation, the diaphragm (or piston) in the pilot valve will push the adjusting spring, change the pilot valve opening.

Main valve: The pilot valve drives the sensitive elements of the main valve (such as diaphragm and piston) by controlling the inlet pressure, which in turn adjusts the opening of the main spool and stabilizes the outlet pressure.

Example: Take Y43H steam pressure reducing valve as an example:

The outlet pressure enters the pilot valve below the diaphragm, pushing the diaphragm to compress the adjusting spring.

Pilot valve to maintain a slightly open state, so that the inlet pressure through the pilot valve acting on the main valve piston cavity, to promote the main spool closed or open.

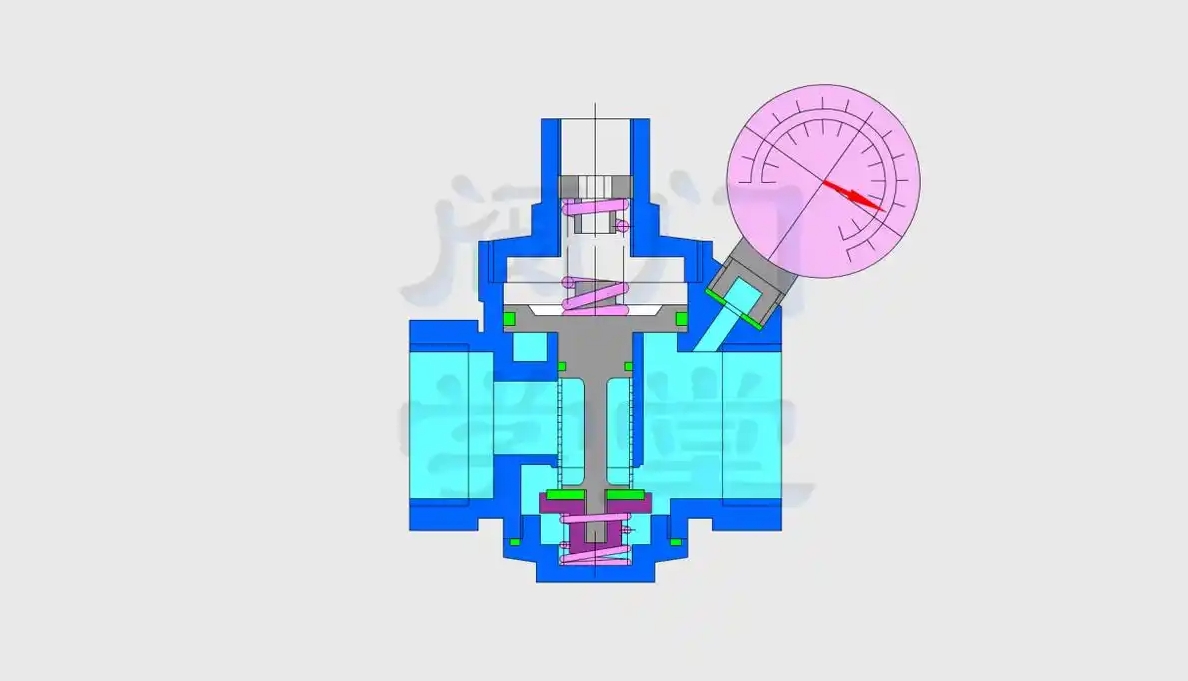

Second, the structure and principle of direct-acting pressure reducing valve

Direct-acting pressure reducing valve to control the spool through direct feedback outlet pressure changes:

The outlet pressure acts directly on the sensitive element (such as piston) below.

When the pressure changes, the piston moves up and down, driving the spool to adjust the opening, to maintain a stable outlet pressure.

Example: Take YZB11X branch pressure reducing valve as an example:

The outlet pressure directly pushes the piston, forming a balance with the adjusting spring on the piston.

When the pressure changes, the piston moves immediately without the intervention of the pilot valve.

Kist Valve Group Details Comparison of key differences between pilot-operated and direct-acting pressure reducing valves

1. Pressure control method

Pilot operated: outlet pressure → pilot valve → control main valve

Direct-acting type: outlet pressure → direct actuation of main valve

2. Spring and size

Pilot operated: Smaller spring, more compact valve.

(Pilot valve with small diaphragm area requires small spring force)

Direct-acting: large spring, volume/weight increases with caliber

(The larger the main valve sensing element, the higher the spring thrust requirement)

3. Accuracy performance (according to GB/T12244-2006)

| Scenario | Direct-acting deviation | Pilot Deviation |

| Pressure fluctuation when flow rate changes | ≤20% | ≤10% |

| Effect of inlet pressure change | ≤10% | ≤5% |

4. Structure and reliability

Pilot type:

✅ High accuracy

❌ Complex structure, high cost

❌ Fine flow path easily blocked by impurities

Direct-acting type:

✅ Simple structure, low failure rate

✅ High resistance to pollution

❌ Lower control accuracy

How to choose between pilot-operated and direct-acting pressure reducing valves?

Select a pilot operated pressure reducing valve:

Requires high precision control (e.g. laboratory, precision equipment)

Allow regular maintenance to clean the flow path

Choose a direct-acting pressure reducing valve:

Limited budget or simple working conditions

Contaminated media (e.g., industrial sites)

Space/weight constraints (large diameter piping)