First, what is an electric ball valve?

Electric ball valve consists of two parts: electric device (control power) and ball valve (control media flow). The electric device drives the ball spool by turning the valve stem to realize the switching, regulating, directional or shunting of the medium. Kist valve group refresh its advantages are:

Remote control: signal transmission is far and accurate, convenient operation.

Flexible installation: supports manual/electrical switching, and a spare handwheel is available in case of power failure.

Strong adaptability: the corner is usually 90 degrees (special ball valve can be adjusted), suitable for different scenes.

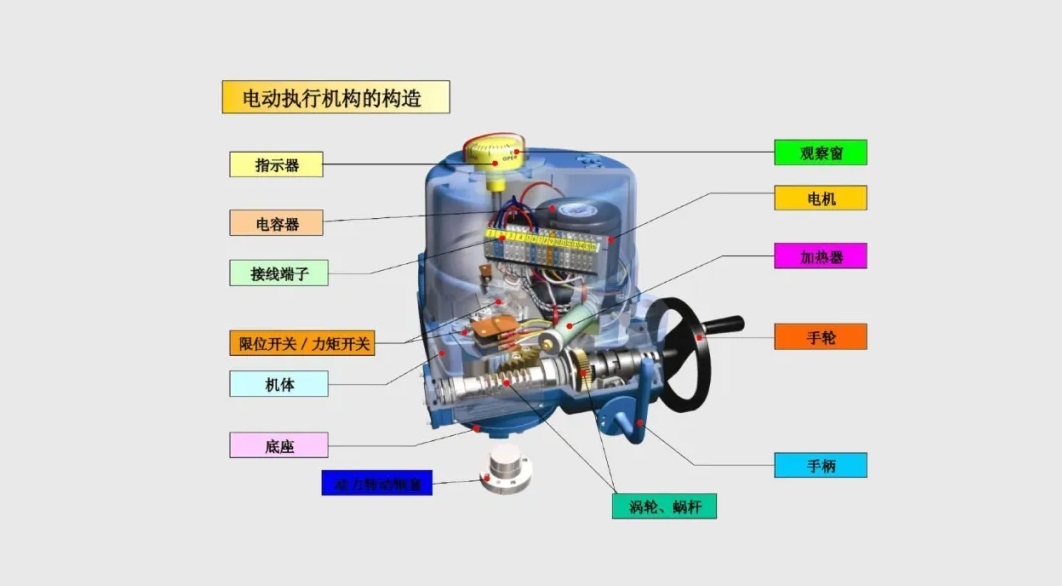

Second, the seven core components of the electric device:

Specialized motor: generate rotary power.

Reduction mechanism: reduce the motor speed and enhance the torque.

Torque control mechanism: prevent the rotary force from exceeding the safety range.

Stroke control mechanism: accurately control the switching position of the valve.

Position indicator: Real-time display of valve opening or closing status.

Manual/electrical switching mechanism: Manual operation can be switched in case of emergency.

Handwheel: Manual switching of the valve group in case of power failure.

Third, the working characteristics of the electric device

1、The regular rotation angle is 90 degrees (some models may be different).

2, in line with a number of industry standards, such as:

JB/T 8528-1997 (ordinary type technical specification)

GB/T 28270-2012 (intelligent type technical specification)

ISO 5211 (high platform ball valve installation standards)

Fourth, how to install electric devices and ball valves?

1、Ordinary ball valve: need to be connected through the bracket and coupling to fix the electric device and valve.

2、High-platform ball valves: direct mounting, no need for bracket (in accordance with ISO 5211 standard), usually square head drive, easy maintenance and replacement.

V. Selection points of electric device

1、Voltage requirements

Support AC 380V/220V/24V (50Hz) or DC 24V/48V, different voltages need corresponding wiring.

2、Environmental adaptability

Temperature range: -30℃~70℃ (according to the model)

Humidity: ≤95%.

Special environment (high temperature/low temperature/humidity) requires customized design, such as low-temperature environment with a heater.

3、Protection grade

Ordinary type: IP65 (dustproof + anti-spray water)

Intelligent type: IP67 (dustproof + short-time water immersion)

4、Switching speed

Conventional 90-degree rotation takes about 30 seconds, large diameter valves are even slower. If you need to cut off quickly, it is recommended to choose pneumatic ball valves.

5、Control type

Switching type: only control open/close

Regulating type: support 4-20mA or 1-5V signal, can set the status of the valve in case of power failure (keep in place / fully open / fully closed).

6、Explosion-proof requirements

Hazardous environments need to select the explosion-proof model (such as d Ⅱ type), applicable to gas, dust explosive scenes.

Six, the ball valve selection points

1、Electrical O-type ball valve

Suitable for switching control, good sealing, can be used for gas or liquid pipeline.

2、Electrical V type ball valve

With V-shaped cutout, can handle media containing fibers and particles, strong anti-blocking, high regulation accuracy.

3、Stainless steel ball valve

Resistant to acid and alkali corrosion, material optional 304, 316, etc., the valve seat is usually PTFE.

4、Fully welded ball valve

Used for natural gas, oil pipelines, to eliminate media leakage.

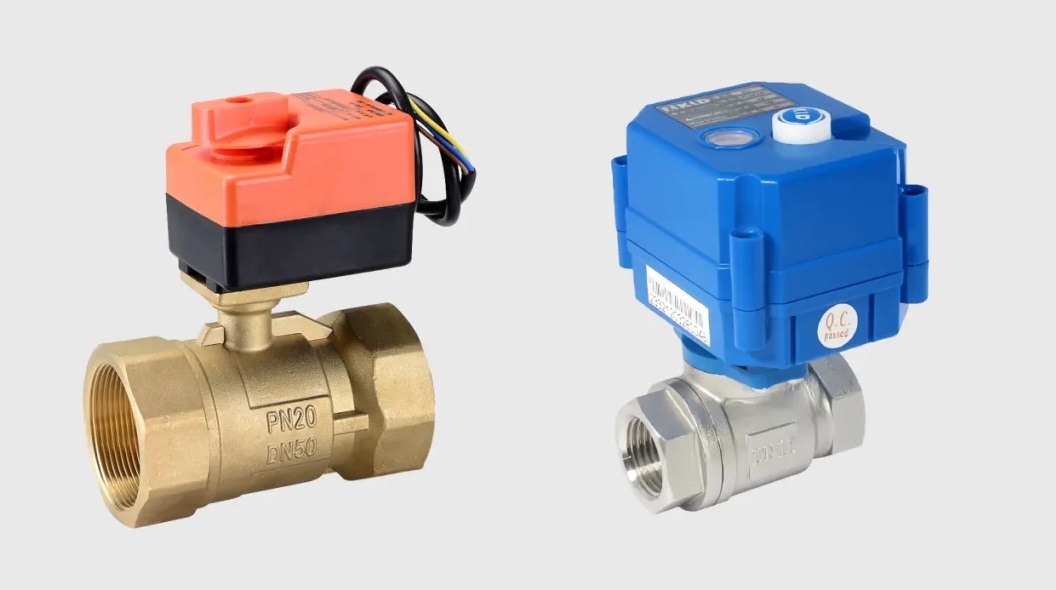

5、Micro ball valve

Suitable for air conditioning, low-pressure small-diameter pipeline, low cost.

6、Hard seal ball valve

Resistant to high temperature, wear resistance, applicable to electric power, petrochemical industry.

VII. Wiring Precautions

Switching feedback is divided into active (external power supply) and passive (self-powered).

Regulating type needs to be connected to the 4-20mA signal line.

The wiring of different brands may be slightly different, need to refer to the manual.

VIII. Future Trends

With the development of industrial automation, electric devices are being upgraded in the direction of miniaturization, digitalization and intelligence. Intelligent electric ball valves will be more widely used in remote monitoring and precision control scenarios.