Spring loaded safety valves are the core components of industrial equipment to ensure system safety, and their core structure is divided into two categories: fully closed and semi-closed (some of the information said "not closed"). The implementation of standards for the “GB/T12243-2021 spring direct-loaded safety valve”.KIST VALVE GROUP introduces the main features, models and differences of fully closed, semi-closed and open type safety valves in detail.

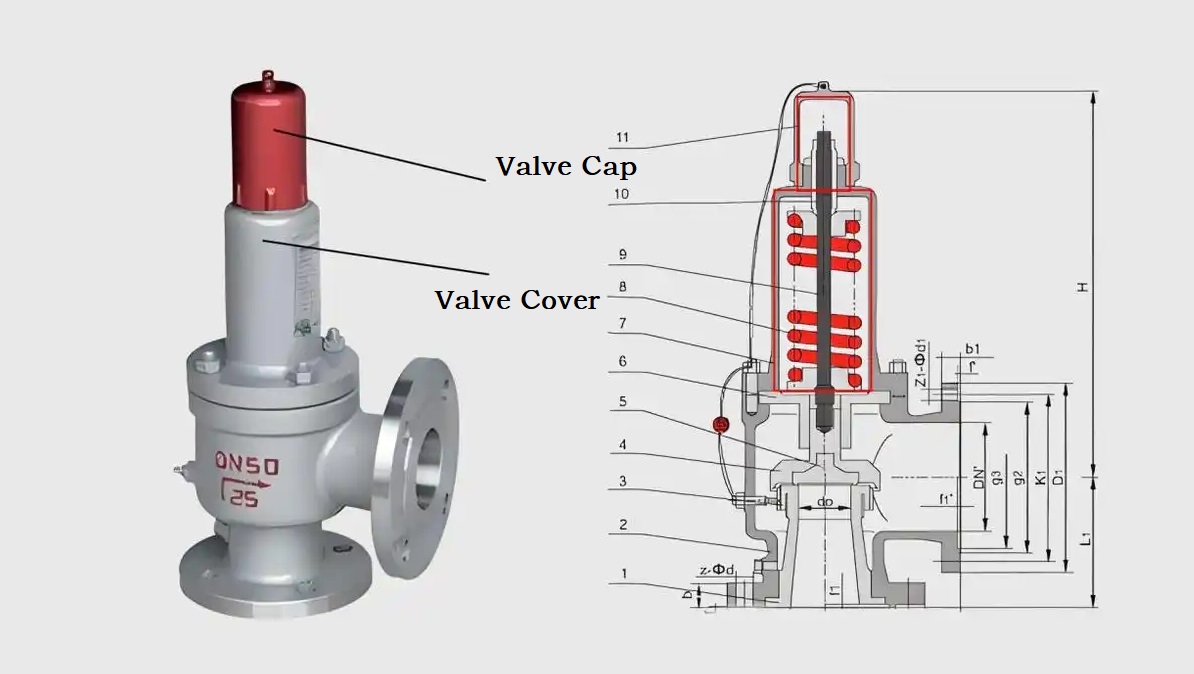

First, fully enclosed safety valve (zero leakage design)

This type is also called fully closed safety valve.

When the valve is opened to release the pressure, the fluid inside (called the medium) will all be discharged through the outlet pipe. There will be no leakage to the outside of the valve.

This design is ideal for media that is flammable, explosive, toxic, or hazardous because safety is paramount.

When the medium is discharged, a small amount of fluid will enter the bonnet through the gap between the valve flap and the guide sleeve, and may then follow the gap between the stem and the regulating sleeve into the bonnet.

The bonnet and the valve body must therefore be well sealed, as must the bonnet and the bonnet. This ensures that the medium does not leak into the external environment.

Special Installation Requirements:

If the valve is installed in a system with additional back pressure or in a closed discharge piping system, the portion of the valve on the discharge side of the outlet needs to be pressure tested (hydraulic strength test). The test pressure needs to be 1.5 times the maximum back pressure.

At the same time, a gas tightness test is required. This is also carried out on the outlet discharge side of the valve at a test pressure equal to the maximum back pressure and not less than 0.2 MPa (MPa). The test needs to last for 3 minutes, during which no leakage is allowed.

Main Product Models:

A42H/Y/F/W Series: Flange Connection Full Opening Safety Valve

A44H/Y Series: Full Opening Safety Valve with Manual Wrench Operation

A40Y Series: Special High Temperature Media Safety Valve Equipped with Heat Sinks

A21H/Y/F/W Series: External Threaded Connection Micro Opening Safety Valve

A41H/Y Series: Flange Connection Micro Opening Safety Valve

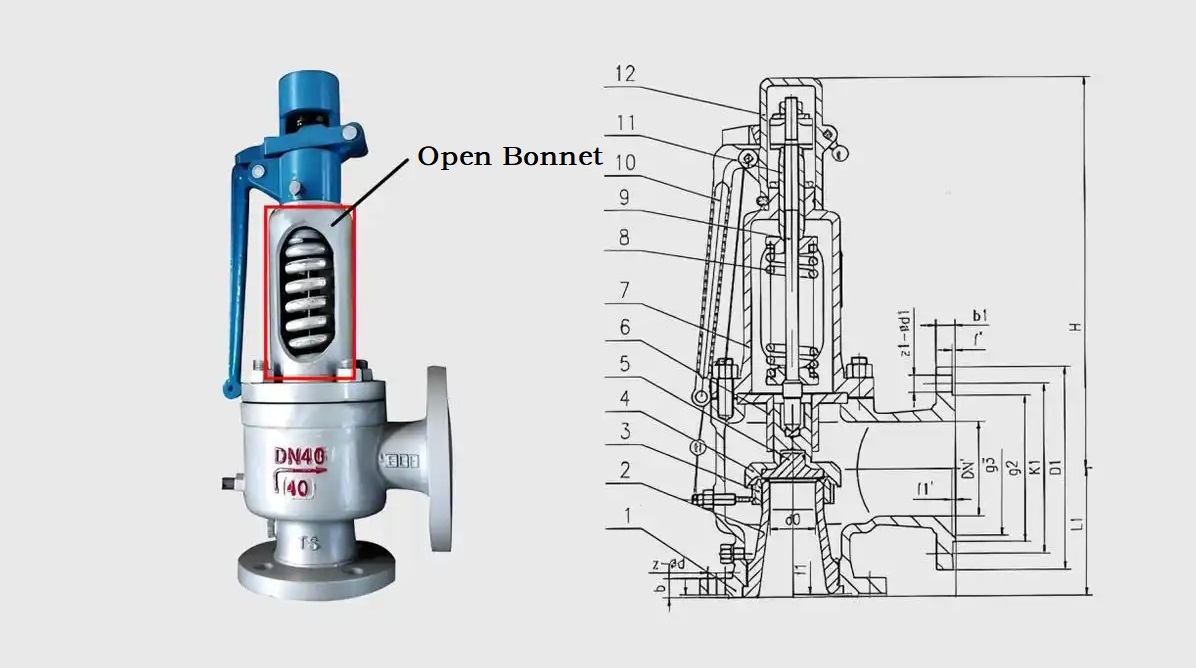

Second, semi-closed safety valve (controlled leakage design)

Working principle:

When the valve is opened, about 70%-80% of the medium is discharged through the discharge piping, and the remaining portion will leak slightly from the stem seal. This design is realized by the open bonnet structure:

Typical structure of A48H/Y type: the bonnet adopts open design, especially suitable for steam medium, which can effectively reduce the impact of high temperature on the performance of the spring (to avoid metal fatigue and elastic decay)>>>Difference between butterfly check valve and swing check valve

Typical application scenarios:

Steam system (e.g. boiler, turbine)

Compressed air system

Ordinary gas media without pollution requirements

Mainstream product models:

A47H/Y series: flange connection with wrench micro-opening safety valve

A27H/Y series: external threaded connection with wrench micro-opening safety valve

A48H/Y series: flange connection full-opening safety valve (for steam)

A28H/Y series: external threaded connection full-opening safety valve

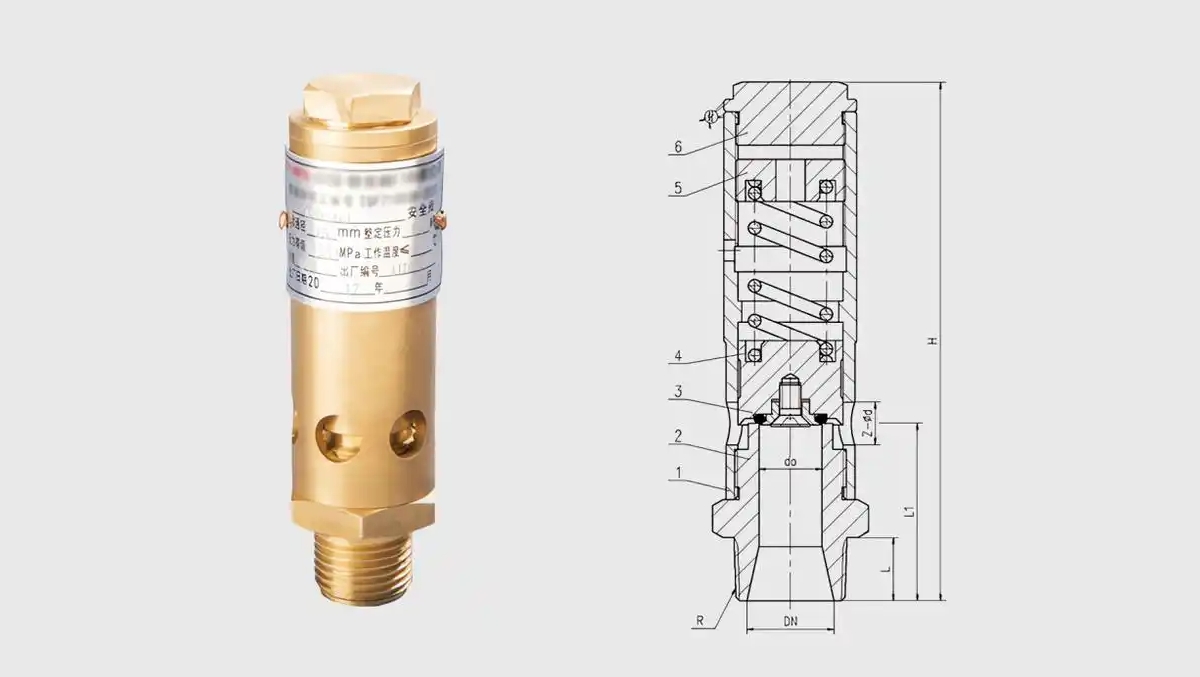

III. Open-ended safety valves (direct vent atmospheric design)

Open type safety valves do not have connecting piping or flange connections at the discharge port, and usually only have a simple discharge hole.

When the valve is opened, the medium is not guided into the pipeline or container, but is discharged directly into the surrounding atmosphere.

This design is only suitable for media that are not at all polluting or hazardous to the atmosphere. The most common example is compressed air.

Application example:

Safety valve for marine air cylinders following the GB/T14087-2010 standard.

Safety valves for small air compressors.

Safety valves for old pressure cookers (also vented directly into the kitchen air).

The main difference

| Features | Fully Closed Safety Valves | Semi-Closed Safety Valves | Open Safety Valves |

| Discharge Methods | All of the media is discharged through the pipeline | Mostly through the pipeline, with a small amount of leakage | Direct discharge to the atmosphere |

| Leakage | No external leakage | Small external leakage | All discharges to the external environment |

| Applicable media | Flammable, explosive, toxic, hazardous | Steam, air (non-polluting) | Compressed air, etc. (absolutely non-polluting) |

| Safety | Highest | Medium | Lowest (only when not harmful to the medium) |

| Environmental friendliness | Highest | Medium | Lowest (only if not harmful to the medium) |

| Cost | Highest | Medium | Usually lowest |

Choosing the right type is very important. The hazardous nature of the medium, the requirements of environmental protection regulations and the cost budget of the project need to be taken into account. Where safety and environmental protection are important, a fully enclosed type must be used; for harmless media such as air or steam, a semi-enclosed or open type may be a more economical choice.

Suggestions for selection:

1. The medium involving personal safety or environmental pollution must be selected fully enclosed type

2. For steam system, prefer A40Y series with heat sink or open type A48H/Y.

3. Cost-sensitive common gas system can choose semi-closed basic models